5 Ways Predictive Maintenance Using Vibration Data Improves Motor Failure Detection

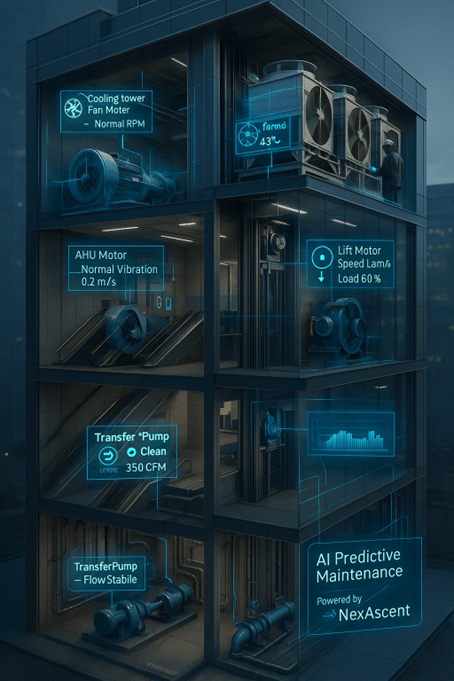

Introduction: Predictive Maintenance for Smart Buildings

In smart buildings, downtime directly affects Overall Equipment Effectiveness (OEE) — a key metric measuring how efficiently assets perform.

Whether it’s an FCU (Fan Coil Unit) motor that maintains indoor comfort or a lift motor responsible for vertical mobility, any unexpected failure reduces availability, raises maintenance costs, and lowers user satisfaction.

By applying predictive maintenance using vibration data, facility managers can detect early signs of motor wear or imbalance. This IoT-driven predictive approach prevents unexpected breakdowns, maximizes uptime, and boosts OEE, ensuring every motor operates at peak performance.

Understanding OEE in Building Operations

OEE (Overall Equipment Effectiveness) evaluates how effectively an asset performs. It combines three essential factors:

| OEE Component | Meaning | Example for FCU or Lift |

| Availability | % of time the equipment operates | Minimizing downtime from motor breakdowns |

| Performance | How efficiently the motor runs | Detecting imbalance or friction that slows the motor |

| Quality | Output that meets target conditions | Maintaining smooth airflow or lift motion |

While a perfect OEE is 100%, most buildings achieve 60–80%. Predictive maintenance using vibration data can raise OEE by improving equipment health and consistency.

Why Predictive Maintenance Is Essential for Motors

Traditional maintenance is reactive or scheduled — both inefficient.

Predictive maintenance (PdM), powered by vibration sensors and AI analytics, transforms maintenance into a data-driven process.

Using vibration data enables facilities to:

- Detect early motor faults before failure

- Avoid unnecessary downtime

- Reduce spare-part and labor costs

- Improve OEE by ensuring higher availability and performance

Research shows that predictive maintenance using vibration analysis reduces unplanned downtime by 50–60%, cuts maintenance costs by 30–40%, and improves OEE by 10–20%.

Why Vibration Data Is the Key to Predicting Motor Failure

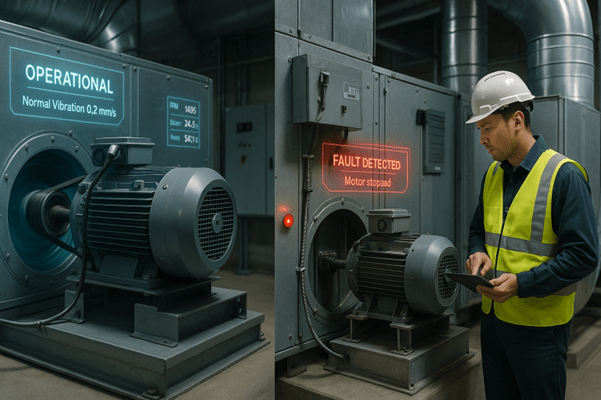

Every rotating motor emits vibration. As components wear or misalign, vibration changes — becoming a reliable indicator of motor health.

| Fault Type | Frequency Signature | Common Cause | Example |

| Imbalance | 1× rotational frequency | Dust on fan blades | FCU impeller |

| Misalignment | 2× rotational frequency | Shaft offset | Lift traction motor |

| Bearing defect | High-frequency spikes | Bearing wear | FCU fan bearing |

| Looseness | Random harmonics | Loose bolts | Lift motor mount |

Monitoring vibration amplitude, RMS velocity, and FFT spectra enables predictive detection long before failure.

IoT Vibration Sensors: The Backbone of Predictive Maintenance

Modern IoT vibration sensors make predictive maintenance using vibration data affordable and wireless.

Typical setup:

- Sensor: e.g., NexAscent Nex-V100

- Gateway: UG65 or UG56 LoRaWAN gateway

- Cloud Platform: AI analytics + dashboard visualization

Measured parameters:

- RMS acceleration (mm/s²)

- Peak vibration (g)

- FFT frequency bands

- Temperature

Data flows via LoRaWAN → MQTT → Cloud Dashboard, where AI models perform anomaly detection and predict potential motor failure.

Step-by-Step Guide: Predicting Motor Failure Using Vibration Data

- Establish Baseline

Record vibration readings from healthy FCU and lift motors. - Continuous Monitoring

Collect live vibration and temperature data. Trigger alerts when readings exceed 25–30% above baseline. - FFT Analysis

Use Fast Fourier Transform (FFT) to detect imbalance (1×), misalignment (2×), or bearing defects (high frequency). - AI Prediction Models

Apply TensorFlow regression or LSTM models to estimate Remaining Useful Life (RUL).

Example: If vibration rises by 0.3 mm/s weekly and failure threshold is 7 mm/s → breakdown predicted in 17 weeks. - Maintenance Action

Alert message:

“Lift Motor #3 shows abnormal bearing vibration — predicted failure in 21 days. Plan maintenance to maintain OEE above 90%.”

This process makes predictive maintenance using vibration data a practical method to optimize uptime.

Applications in Smart Buildings

-

Predictive Maintenance for FCU Motors

In hotels, malls, and offices, FCU motors ensure occupant comfort.

Vibration-based predictive maintenance offers:

- Early detection of imbalance or bearing wear

- Reduced unplanned downtime

- 25–30% longer motor lifespan

- Higher OEE through improved availability

-

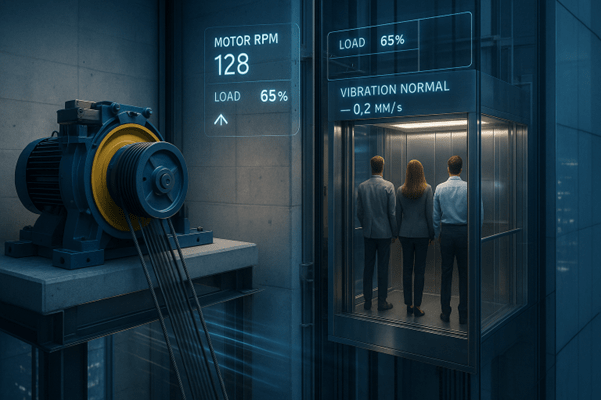

Predictive Maintenance for Lift Motors

Lift reliability is critical for tenant satisfaction and safety.

Monitoring vibration enables:

- Detection of gear or bearing faults

- Identification of rope slippage and misalignment

- Prevention of overheating from friction

With predictive maintenance using vibration data, buildings can achieve near-100% lift uptime and improved OEE.

Integrating Predictive Maintenance with BMS

Predictive maintenance using vibration data integrates seamlessly with existing Building Management Systems (BMS).

Typical workflow:

- Sensor → LoRaWAN Gateway (UG65)

- Gateway → MQTT Broker → Cloud AI Analytics

- Cloud → Dashboard & OEE Report

Dashboards visualize:

- Real-time vibration graphs

- Motor health scores

- Remaining Useful Life

- OEE components: Availability, Performance, Quality

This integration provides a unified view of building performance and predictive insights.

Lifts are important transportation within buildings

OEE as a Key KPI for Predictive Maintenance

Linking OEE metrics to predictive maintenance using vibration data helps quantify improvement:

| KPI | Before PdM | After PdM | Improvement |

| Availability | 85% | 95% | +10% |

| Performance | 88% | 94% | +6% |

| Quality | 97% | 98% | +1% |

| Overall OEE | 72% | 87% | +15% |

This tangible improvement demonstrates ROI and justifies continued investment in vibration-based predictive maintenance.

Implementation Roadmap for Predictive Maintenance

| Step | Description | Tools |

| 1 | Install vibration & temperature sensors | Milesight EM500-VIB, EM310, Nex-V100 |

| 2 | Set baseline readings & thresholds | 2.0 mm/s RMS for FCU motors |

| 3 | Develop AI analytics pipeline | TensorFlow, Node-RED, InfluxDB |

| 4 | Integrate with OEE dashboards | Grafana, NexAscent platform |

| 5 | Configure alert system | Telegram, Email, BMS integration |

Start small with 5–10 assets, then expand after validation.

ROI and Business Impact

| Metric | Typical Gain |

| Maintenance cost | ↓ 30–40% |

| Downtime | ↓ 50–60% |

| Energy efficiency | ↑ 10–15% |

| Motor lifespan | ↑ 25–30% |

| OEE score | ↑ 10–20% |

| Payback period | 6–12 months |

Predictive maintenance using vibration data is not just failure prevention — it’s an OEE optimization strategy that delivers measurable business returns.

Challenges and Best Practices

Challenges

- Accurate baseline calibration

- Data noise from nearby machines

- Limited training data for AI models

Best Practices

- Mount sensors firmly for precise vibration capture

- Combine vibration, temperature, and current data

- Use AI trend analysis to filter false alarms

- Incorporate OEE tracking from deployment stage

Conclusion: The Future of Predictive Maintenance and OEE

Predictive maintenance using vibration data transforms operations from reactive to intelligent.

For FCU and lift motors, continuous monitoring powered by IoT and AI ensures early fault detection, minimized downtime, and maximized OEE.

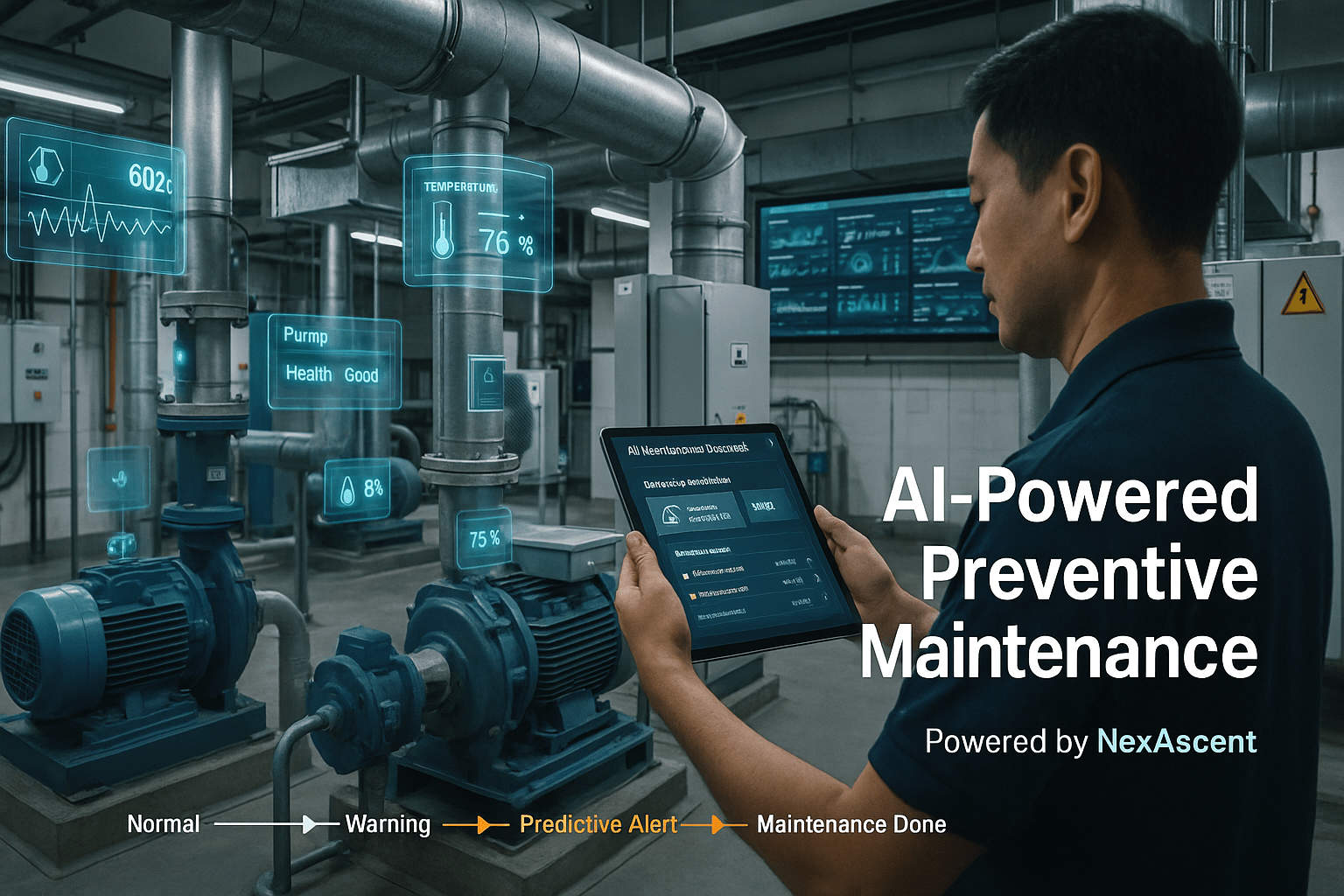

Contact NexAscent to find out more info on how preventive maintenance solution help you reduce unplanned downtime.