Smart Factory

Modern factories face mounting pressure to achieve higher productivity, reduce downtime, and meet stringent quality and sustainability goals — all while managing aging assets, fragmented systems, and manual processes.

Many operations still rely on periodic checks and siloed monitoring tools, making it difficult to detect early faults, measure energy waste, or unify data across equipment and control systems.

Our Solution: Intelligent Industrial Monitoring

NexAscent’s Smart Factory framework connects machines, sensors, and systems to deliver real-time visibility, predictive insights, and seamless automation — helping factories evolve toward Industry 4.0.

01.

Vibration & Condition Monitoring Sensors

Monitor vibration amplitude, frequency, and temperature on motors, pumps, compressors, and fans.

Using AI-based pattern recognition, early signs of imbalance, bearing wear, or misalignment are detected — enabling preventive maintenance before costly breakdowns occur.

Key benefits:

- Predictive maintenance alerts

- Reduction of unplanned downtime

- Extended machine lifespan

- Integration with WinCC or custom dashboards

02.

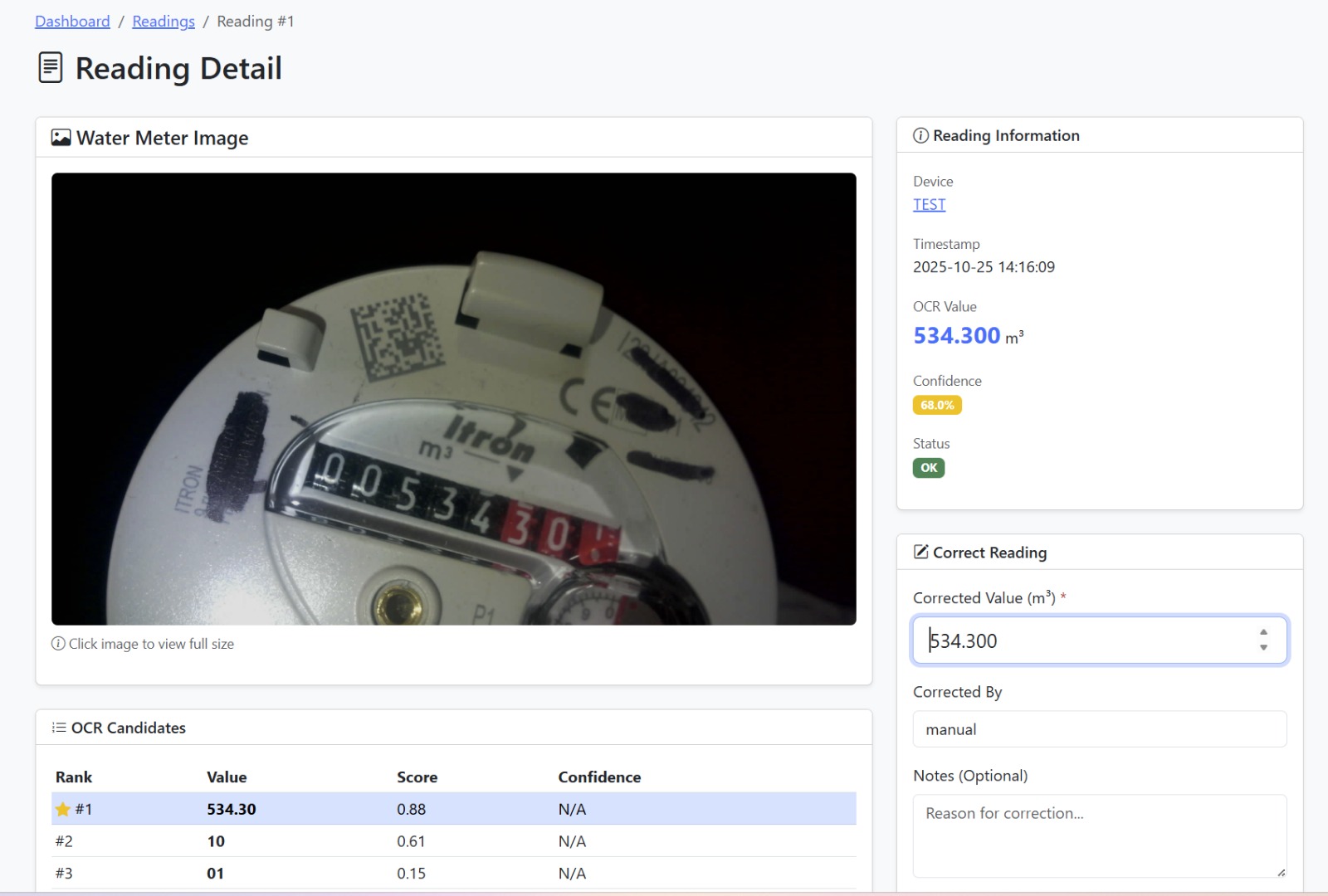

Camera-based OCR & Computer Vision

Smart cameras read meter displays, gauges, or production labels automatically using AI-based OCR (Optical Character Recognition).

Ideal for sites with legacy meters, energy monitoring, or visual quality checks — no human entry required.

Applications:

- Reading analog electricity/water/gas meters

- Detecting product labels or lot codes

- Counting production units

- Safety & anomaly detection on factory floors

03.

Energy Monitoring & Analytics

Smart power sensors and sub-meters track energy consumption at machine, line, and building levels.

These devices capture voltage, current, power factor, and energy trends in real time and integrate seamlessly with existing SCADA or IoT platforms.

Combined with AI analytics, the system identifies inefficiencies, abnormal loads, and idle energy usage.

Applications:

- Real-time monitoring of machinery energy draw

- Load balancing across production lines

- Power quality analysis (voltage dips, harmonics)

- Energy benchmarking by shift or production output

04.

Industrial Integration & Automation Services

Our engineering team supports integration across all levels of your plant ecosystem.

Services include:

- WinCC setup & dashboard integration

- Modbus / BACnet gateway configuration for legacy PLCs and BMS systems

- MQTT / LoRaWAN connectivity for modern IoT networks

- Database & dashboard design for real-time analytics

- Alarm & notification setup for maintenance or safety events

05.

Centralised Dashboard & Analytics Platform

All data is visualised on a single cloud or on-premise dashboard — offering live KPIs, trend analytics, and AI-based predictions.

Dashboard Features:

- Machine status & OEE tracking

- Vibration trend plots & predictive alerts

- Energy consumption heatmaps

- Environmental monitoring

- OCR data logs & image archive

- Integration to WinCC / BACnet / Modbus networks

ROI and Business Case

Smart landscaping solutions deliver tangible business returns for clients

Reduced Downtime (30–60 %)

Predict and act before failures occur.

Energy Savings (10–25 %)

Identify inefficiencies and optimize loads

Improved Quality & Traceability

OCR and vision ensure data accuracy.

Unified Visibility

One dashboard for all machines and systems.

Scalable Architecture

Works with both modern and legacy assets.

Conclusion

NexAcent’s Smart Factory solutions empower industrial sites to transition toward digital, data-driven operations.

From machine-level sensors to enterprise-wide analytics, our LoRaWAN, Modbus, and BACnet integrations ensure every piece of equipment is connected, visible, and optimized — paving the way for predictive maintenance, operational excellence, and sustainable manufacturing.